Mobile wastewater treatment system

We filter wastewater in the cycle

Product

The mobile system is integrated in a 20 foot container and is able to filter up to 200 l / min of polluted process waste-water, that can instantly be re-used on spot as clear water.

Fully automatical, flexible and ecological. In one closed cycle.

The compact construction of our system in a container allows 100% mobility. It only takes few hand moves to get the full automatic wastewater treatment plant, on every construction site, in all climate zones of this earth up and running.

Even removal material, that is hard to filter, can be filtered in one operating sequence.

5-10% of the polluted process wastewater is separated as solid material and 90 to 95% are re-cycled back to clean water quality of less than 1 μm particle size. After this process the clean water is lead back to the high-pressure pump for re-use.

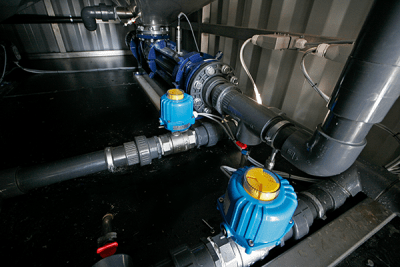

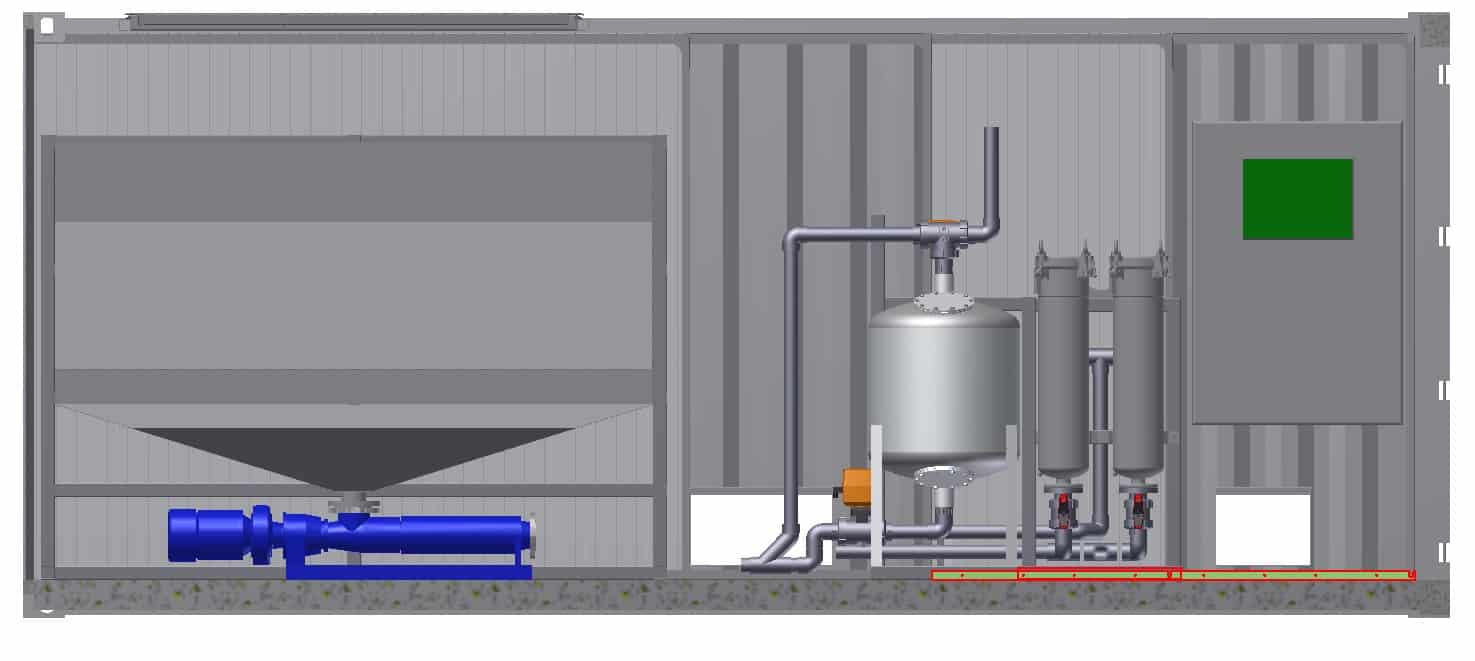

The functional sequences of the container filtration system are fully automated. The pH-value is monitored permanently and regulated if required.

For projects with higher quantities of wastewater, we develop with our customers project-specific, individual solutions.

The mobile Reprotex wastewater treatment systems are made in Austria and produced by local specialists.

The mobile Reprotex wastewater treatment system is available under the product name MFD_R200.

| Technical Specifications | |

|---|---|

| 20′ LC Container (insulated) | 6m x 2,4m x 2,6m |

| Weight empty | 5.500 kg |

| Flow rate | stepless up to 200l per minute |

| Filter rate | up to 1 μm |

| Power supply | 400 V, 50 Hz, 8kW |

| Charateristics | |

|---|---|

| Procedure | chemically-physically |

| pH value neutralisation | Carbondioxide |

| Recording | pH-value, turbidity, flow rate |

| Control | Fully automated |

| Remote maintenance /- access | 3G/4G |

Operating principle

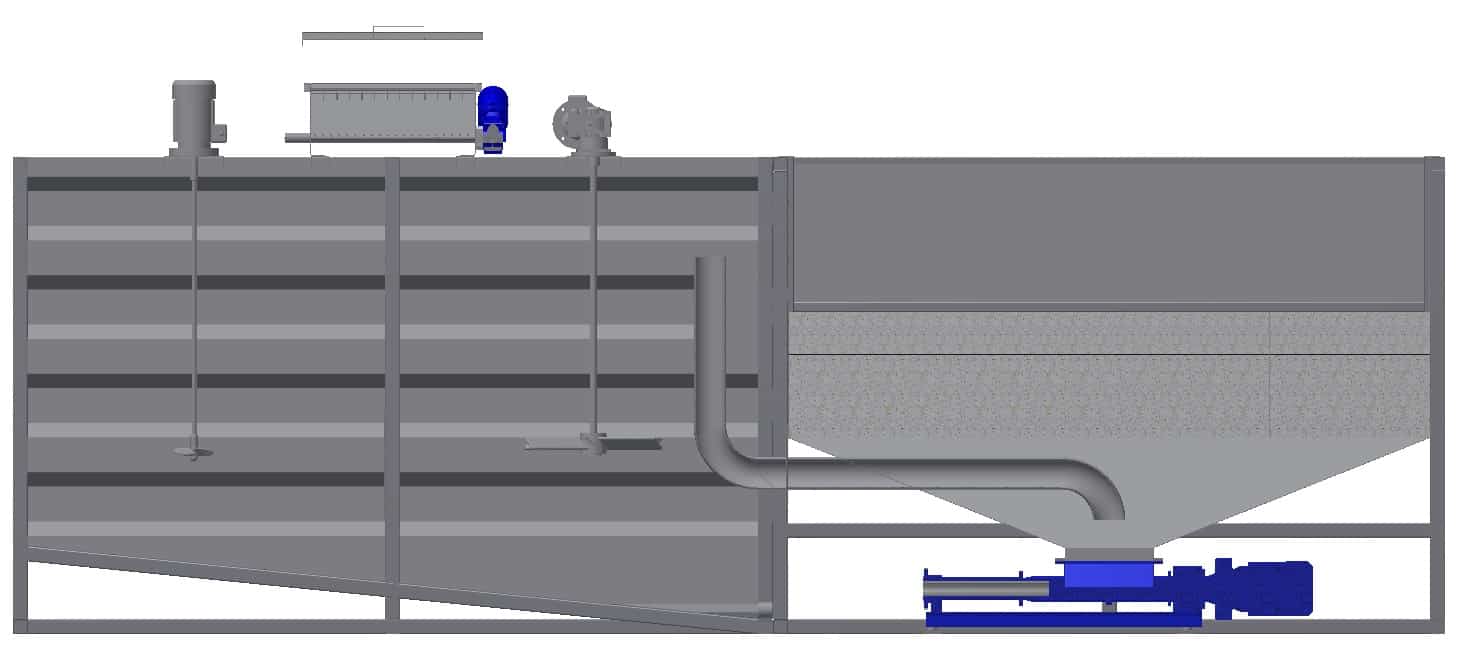

The mobile wastewater treatment system is based on a chemically-physically method, that is able to filter particles out of the wastewater which arise in the operating process.

To do so, floccing agents are added to the polluted wastewater which results in a chemical precipitation and is followed by flocculation. Those phases are split through sedimentation.

The sludge is pumped to the outside, by using a sump pit.) The pre-clear water gets also pumped outside by passing various fine filtration units at a final particle size of less than 1μm.

After this treatment it can be re-used or discharged as clear water. The plant is running as an independent interface from the high-pressure system and is operating between the collected wastewater and the treated clear water.

Applications

The options to use the mobile wastewater treatment system are broad. In a lot of industries working with water as working fluid, the water can not be re-used after one cycle, as it becomes too polluted during the working process. Especially during high-pressure use (up to 4.000 bar) the water can not be re-used as the water quality needs to be very high. But also in industries working with lower pressure and as washing water, only clean water can be used.

The main industries are:

Benefits

To complete our current portfolio, we are also offering a tunnel-cleaning-train. This is the first system worldwide, that is recycling the processed waste water in a permanent circulation directly on the moving train.